Sakuu partners with LiCAP Technologies for electrode supply for solid-state batteries

Green Car Congress

NOVEMBER 17, 2022

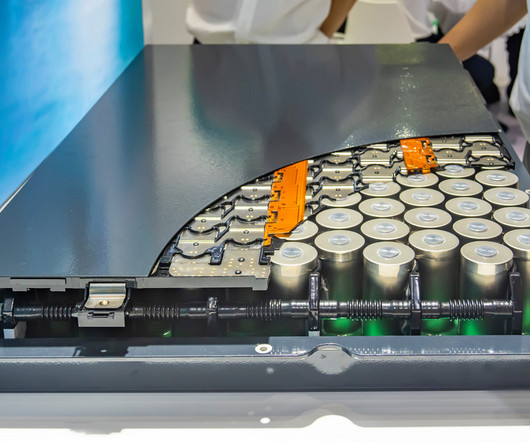

Sakuu, the developer of Swift Print solid-state battery technology ( earlier post ), entered into a memorandum of understanding (MOU) with LiCAP Technologies , a provider of sustainable and scalable electrode coating solutions. LiCAP first processes a blend of battery materials and adds a proprietary compound to activate the formulation.

Let's personalize your content