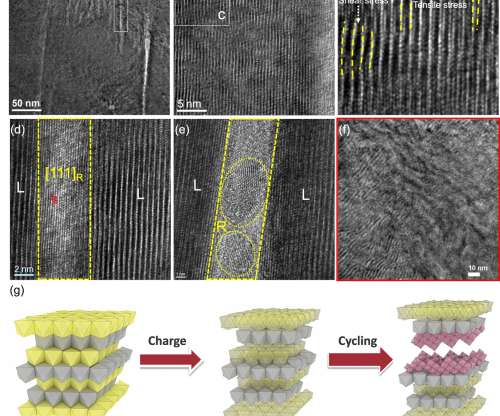

Argonne researchers find cathode material synthesis a key reason for performance degradation of sodium-ion batteries

Green Car Congress

MARCH 25, 2022

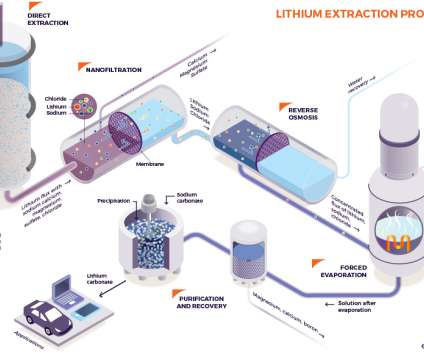

One of the more promising candidates for batteries beyond the current standard of lithium-ion materials is the sodium-ion (Na-ion) battery. Na-ion is particularly attractive because of the greater abundance and lower cost of sodium compared with lithium. In addition, when cycled at high voltage (4.5

Let's personalize your content