Monash researchers stabilize Li-S battery with saccharide-based binder

Green Car Congress

SEPTEMBER 14, 2021

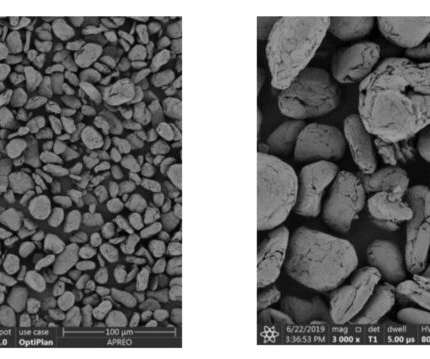

Researchers from the Monash Energy Institute, with colleagues from CSIRO, have used a saccharide-based binder system to develop a durable sulfur cathode with minimal polysulfide escape in a lithium-sulfur battery. the viability of many emerging technologies, for example in aviation, require lighter-weight batteries.

Let's personalize your content