Lyten introduces next generation Lithium-Sulfur battery for EVs; 3X energy density of Li-ion

Green Car Congress

SEPTEMBER 23, 2021

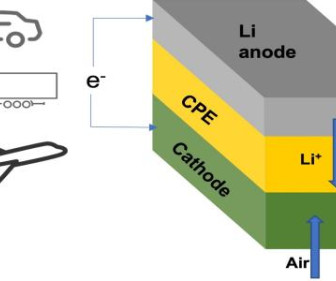

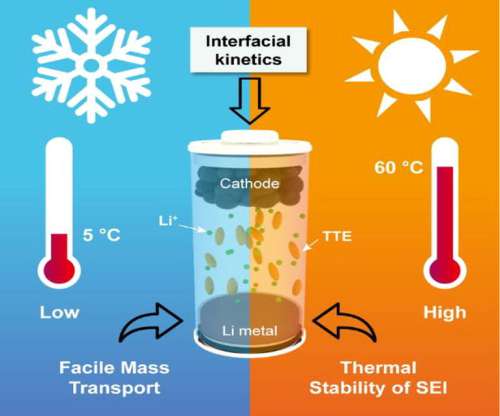

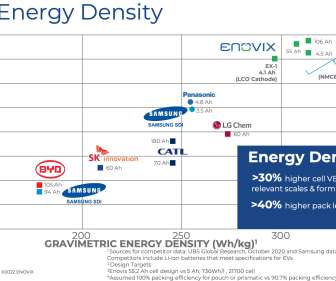

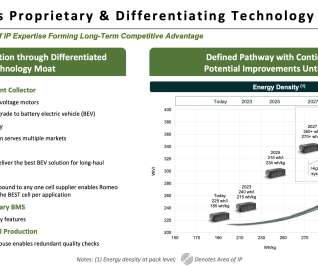

Lyten , an advanced materials company, introduced its LytCell EV lithium-sulfur (Li-S) battery platform. The technology is optimized for the electric vehicle market and is designed to deliver three times (3X) the gravimetric energy density of conventional lithium-ion batteries. Extended range and/or increased payloads.

Let's personalize your content