KIT concept for simultaneous coasting and drying of two-layered electrodes could speed production and lower costs

Green Car Congress

NOVEMBER 14, 2021

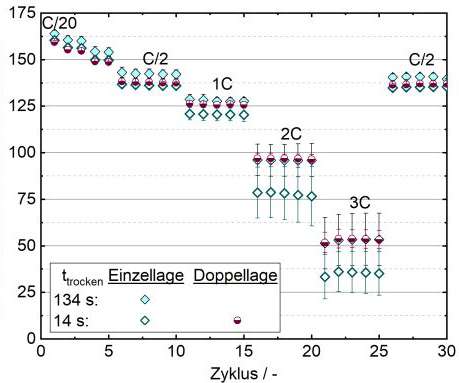

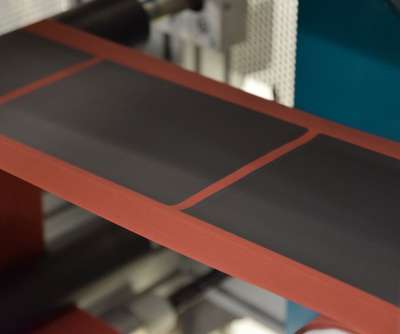

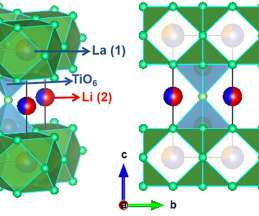

Researchers at the Karlsruhe Institute of Technology (KIT) have developed and successfully tested an innovative concept for simultaneous coating and drying of two-layered electrodes. The results are reported in an open-access paper in the journal Energy Technology. Figure: Jana Kumberg, KIT).

Let's personalize your content