China’s first large-scale sodium-ion battery charges to 90% in 12 minutes

Baua Electric

MAY 17, 2024

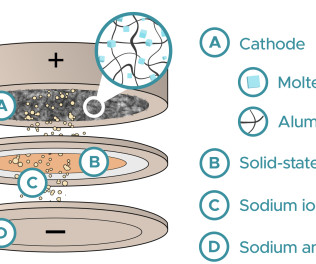

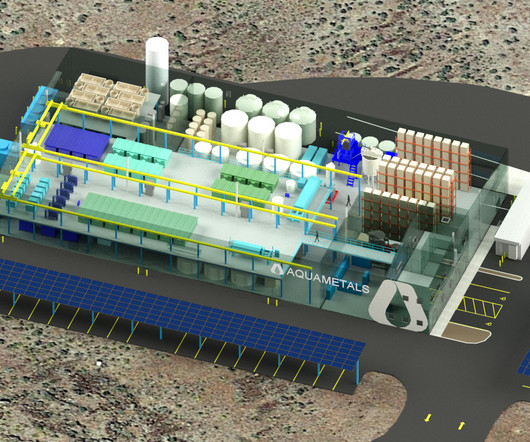

Photo: China Southern Power Grid Energy Storage China’s first major sodium-ion battery energy storage station is now online, according to state-owned utility China Southern Power Grid Energy Storage. It’s comparable to the efficiency of common lithium-ion battery storage systems, at 85-95%. The system comprises 22,000 cells.

Let's personalize your content