New high-performance silicon@graphitic nanowire array Li-ion anode shows excellent cycling stability

Green Car Congress

NOVEMBER 11, 2013

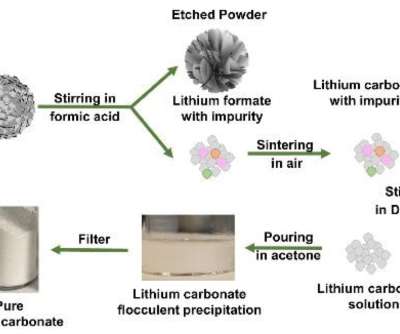

Cross-sectional view of a proposed textured silicon@graphitic carbon nanowire (t-Si@G NW) array electrode configuration. 1 for Li 15 Si 4 at room temperature)—almost ten times that of commercialized graphite anodes. . Credit: ACS, Wang et al. Click to enlarge. —Wang et al.

Let's personalize your content