New long-duration, extended capacity Na-Al battery design for grid storage

Green Car Congress

MARCH 2, 2023

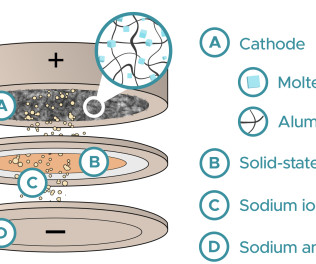

Researchers led by the Department of Energy’s Pacific Northwest National Laboratory (PNNL) have extended the capacity and duration of sodium-aluminum batteries. The new sodium-based molten salt battery uses two distinct reactions. of peak charge capacity. mAh cm −2 , a discharge duration of 28.2 —Weller et al.

Let's personalize your content