Study Suggests Automakers Lose $6,000 On Each EV Sold

The Truth About Cars

MARCH 21, 2024

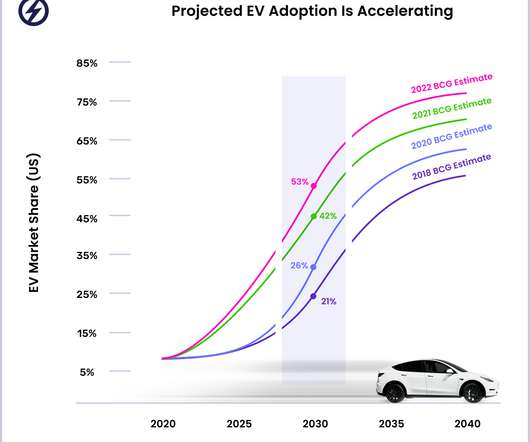

A new study is claiming that automakers lose an average of $6,000 for every $50,000 electric vehicle they sell. Boston Consulting Group, an American-based global management consulting firm that issued the report, said the figure accounts for customer tax credits — painting a rather bleak picture for the future of EVs.

Let's personalize your content