German power-to-gas facility opens green methanation plant; €28M STORE&GO project

Green Car Congress

MAY 13, 2018

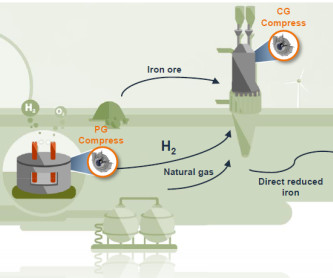

A methanation plant expansion to the existing power-to-gas (PtG) facility in Falkenhagen, Germany has officially opened as part of the international €28-million (US$33.5-million) While the current facility feeds pure hydrogen (“WindGas”) directly into the gas grid, the new methanation plant provides for the generation of “green” methane.

Let's personalize your content