Researchers develop MOF membrane coating to prolong lithium–sulfur battery life

Green Car Congress

SEPTEMBER 8, 2018

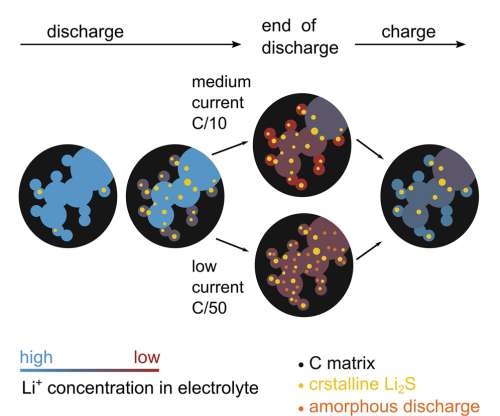

Although rechargeable lithium–sulfur (Li–S) batteries promise high energy density storage—particularly attractive for electric vehicle applications—the technology is currently limited by the shuttling polysulfides between the battery’s electrodes. of its capacity after 40 hours. Shruti Suriyakumar, A. Manuel Stephan, N.

Let's personalize your content