Sparc Technologies, QUT partner to develop a hard carbon anode material from bio-waste for Na-ion batteries

Green Car Congress

SEPTEMBER 13, 2022

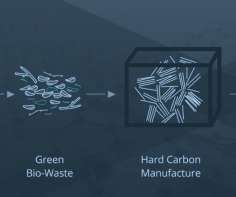

The partnership will begin with a project in the battery anode space with the development of a novel process for the production of hard carbon from bio-waste. Using readily available, sustainable bio-waste material will provide Sparc with a strong environmental value proposition when compared with conventional sources of hard carbon.

Let's personalize your content