New solid-electrolyte interphase may boost prospects for rechargeable Li-metal batteries

Green Car Congress

MARCH 12, 2019

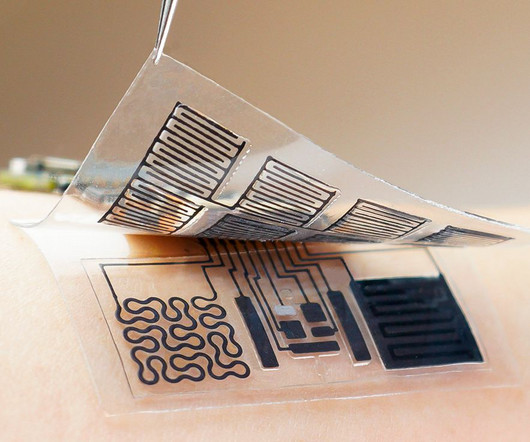

Rechargeable lithium metal batteries with increased energy density, performance, and safety may be possible with a newly-developed, solid-electrolyte interphase (SEI), according to Penn State researchers. In this project, we used a polymer composite to create a much better SEI. Mallouk, Evan Pugh University Professor of Chemistry.

Let's personalize your content