Ceramatec licensing molten sodium technology for heavy oil upgrading; removing the need for diluent for bitumen

Green Car Congress

APRIL 10, 2013

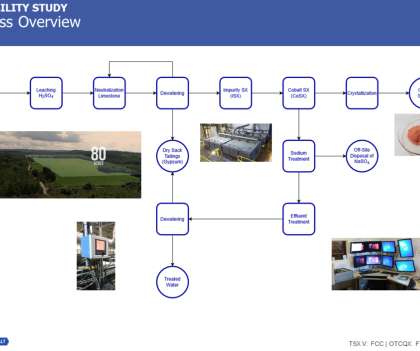

Flowchart of Molten Sodium Upgrading process. The technology, developed by Ceramatec and managed by the Office of Fossil Energy’s National Energy Technology Laboratory (NETL), has been licensed to Western Hydrogen of Calgary for upgrading bitumen or heavy oil from Canada. Source: Field Upgrading. Click to enlarge. Click to enlarge.

Let's personalize your content