Ultium battery cells from GM electric vehicles have an official recycler: Canada's Li-Cycle

Green Car Reports

MAY 12, 2021

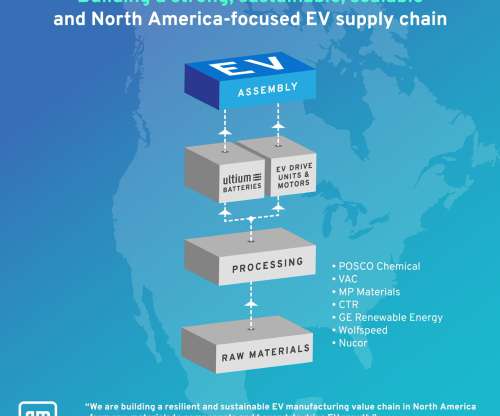

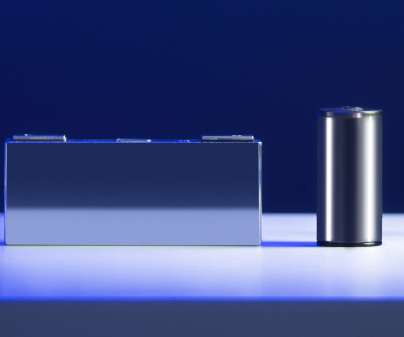

The Canadian firm Li-Cycle will recycle leftover raw material from the manufacturing of Ultium battery cells for upcoming General Motors electric cars, the automaker announced Tuesday in a press release.

Let's personalize your content