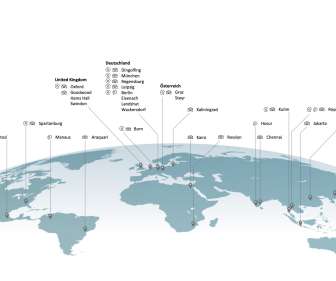

BMW Group secures CO2-reduced steel for global production network

Green Car Congress

NOVEMBER 17, 2022

Following initial contracts with European suppliers, the BMW Group has now concluded further 2 -reduced-steel-for-global-production-network">agreements for the supply of CO 2 -reduced steel in the US and China. Steel is one of the main sources of CO 2 emissions in our supply chain.

Let's personalize your content