Cornell team develops aluminum-anode batteries with up to 10,000 cycles

Green Car Congress

APRIL 6, 2021

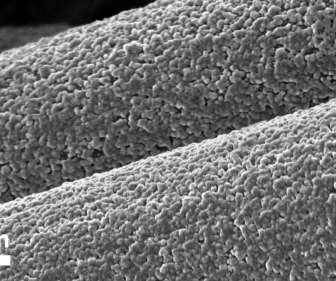

Friend Family Distinguished Professor of Engineering, have been exploring the use of low-cost materials to create rechargeable batteries that will make energy storage more affordable. This magnified image shows aluminum deposited on carbon fibers in a battery electrode. A paper on the work is published in Nature Energy.

Let's personalize your content