Review of co-processing of biocrudes in oil refineries

Green Car Congress

JANUARY 1, 2023

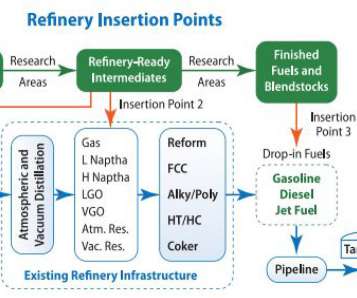

Liquid intermediates from pyrolysis and hydrothermal liquefaction (HTL) can be co-processed in an oil refinery along with conventional crude oil. After pyrolysis, the vapors are condensed to give a dark brown fast pyrolysis bio-oil (FPBO). In fast pyrolysis, biomass is quickly heated to around 500 °C in the absence of oxygen.

Let's personalize your content