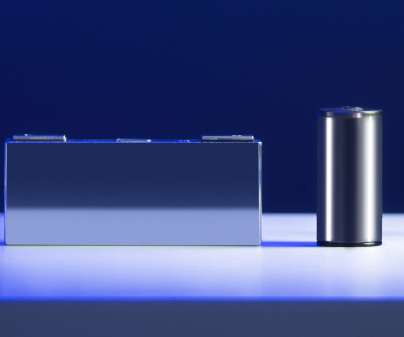

Groundbreaking for Mercedes-Benz battery recycling factory in Kuppenheim, Germany

Green Car Congress

MARCH 4, 2023

This investment strengthens the role of the Kuppenheim site within the global Mercedes-Benz production network and marks a decisive step for Mercedes-Benz’s sustainable business strategy as it moves towards going “Electric Only”.

Let's personalize your content