KIT coordinating EPIC project; accelerated drying of electrodes for Li-ion batteries

Green Car Congress

SEPTEMBER 8, 2020

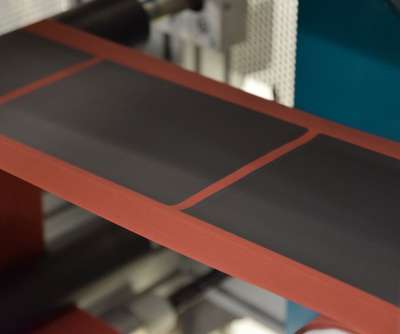

The new EPIC project coordinated by Karlsruhe Institute of Technology (KIT) is aimed at accelerating the drying of high-quality electrodes for lithium-ion batteries, increasing the energy efficiency of this process and, hence, reducing the cost of production. Photo: Ralf Diehm/KIT).

Let's personalize your content