thyssenkrupp greenlights construction of €2B hydrogen-powered direct reduction plant for low-CO2 steel

Green Car Congress

SEPTEMBER 9, 2022

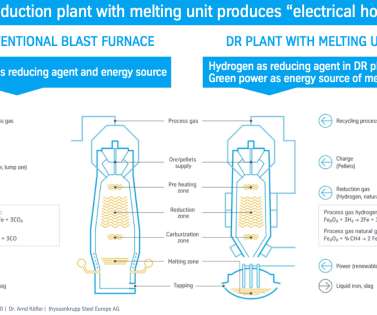

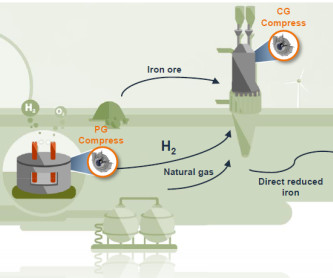

thyssenkrupp will build a €2B hydrogen-powered direct reduction plant at its Duisberg site. We are firmly convinced of this, and this is also borne out by this investment, which heralds a new era for steel production in the Ruhr region. The liquid product is processed into the proven steel grades there. Capacity will be 2.5

Let's personalize your content