Government of Canada, Québec invest in GM-POSCO CAM plant in Québec

Green Car Congress

JUNE 1, 2023

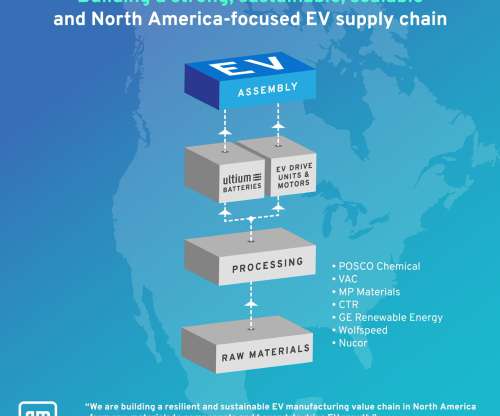

CAM are key battery materials that consist of components such as processed nickel, lithium and other materials that make up about 40% of the cost of a battery. The GM-POSCO joint venture, called Ultium CAM, will create around 200 jobs and strengthen Canada’s electric vehicle (EV) ecosystem and economy for years to come.

Let's personalize your content