Drexel team develops stable Li-S battery with carbonate electrolyte

Green Car Congress

FEBRUARY 14, 2022

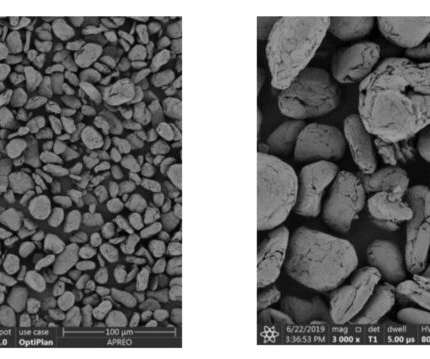

sulfur phase within carbon nanofibers that enables successful operation of Lithium-Sulfur (Li-S) batteries in carbonate electrolyte for 4000 cycles. Carbonates are known to adversely react with the intermediate polysulfides and shut down Li-S batteries in first discharge. —Pai et al.

Let's personalize your content