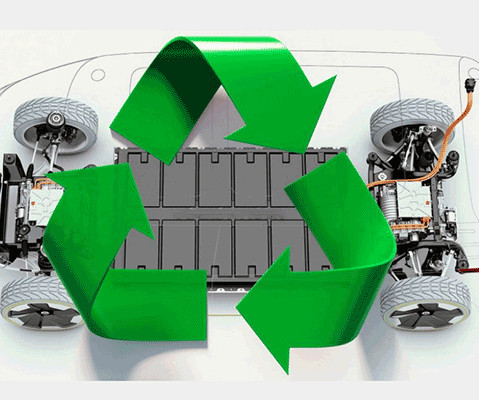

BMW Group creates closed recycling loop for high-voltage batteries in China

Green Car Congress

MAY 27, 2022

The BMW Brilliance Automotive joint venture (BBA) has established a closed loop for reuse of the raw materials nickel, lithium and cobalt from high-voltage batteries that are no longer suitable for use in electric vehicles. The raw materials obtained in this way are then used in production of new battery cells for the BMW Group.

Let's personalize your content