First hydrogen supply chain demonstration project using MCH to transport H2 starts

Green Car Congress

JUNE 30, 2020

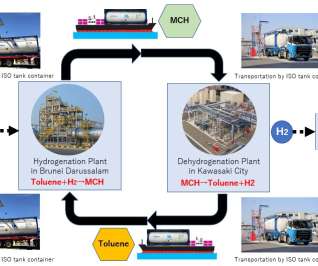

In the supply country, hydrogen, chemically fixed to toluene, is converted by a hydrogenation reaction into methylcyclohexane (MCH), a liquid at ambient temperature and pressure, for storage and transport. In the consumer country, hydrogen is extracted from MCH by a dehydrogenation reaction and supplied as hydrogen gas.

Let's personalize your content