Piedmont Lithium selects Tennessee for second lithium hydroxide project; 30,000 metric tons per year

Green Car Congress

SEPTEMBER 11, 2022

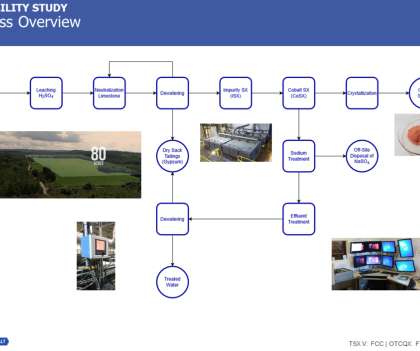

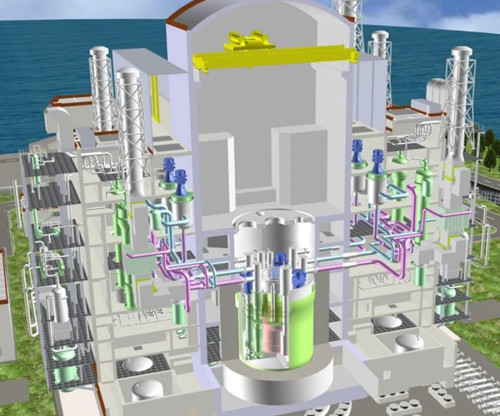

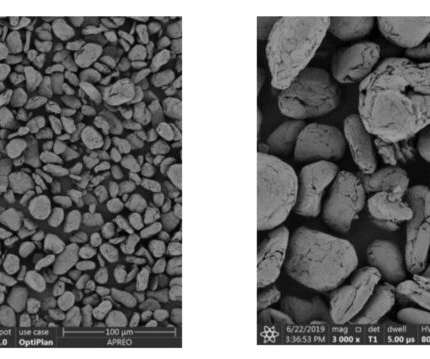

The project will convert spodumene concentrate sourced principally from Piedmont’s international project investments to expand significantly the US supply of lithium hydroxide, a key component in the manufacturing of EV batteries. Front-End Engineering Design (FEED) for Tennessee Lithium will be performed by Kiewit and Primero.

Let's personalize your content