TANAKA establishes production system in China for fuel cell electrode catalysts

Green Car Congress

SEPTEMBER 13, 2023

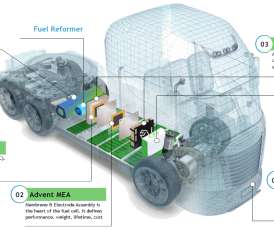

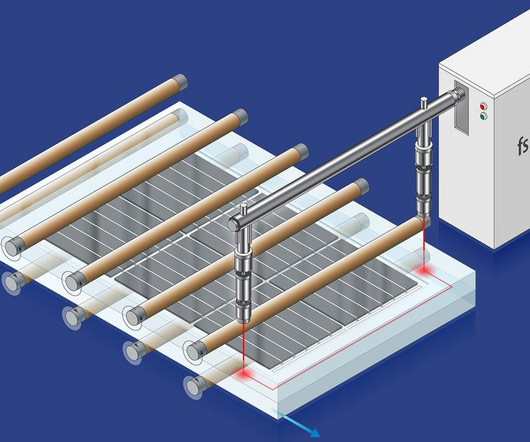

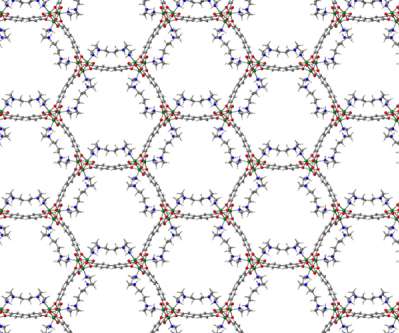

Electrode catalysts for polymer electrolyte membrane fuel cells (PEFCs) As part of the agreement, production equipment will be installed at the plant of Ya’an Guangming Paite Precious Metal Co., One major issue facing the full-scale use of fuel cells is the cost of the platinum they use. TANAKA Kikinzoku Kogyo K.K.,

Let's personalize your content