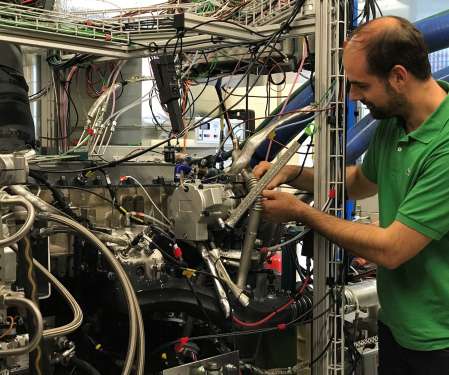

Fraunhofer IFF team designing hydrogen factory of the future

Green Car Congress

APRIL 11, 2020

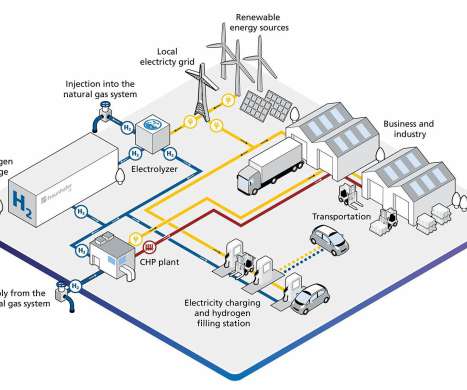

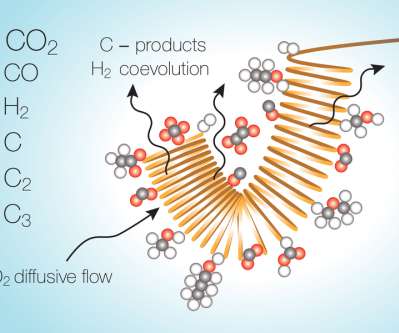

Researchers at the Fraunhofer IFF in Germany are designing the distributed and modular production and distribution of green hydrogen for industry, business and transportation throughout the value chain—a hydrogen factory of the future. The hydrogen factory of the future. © Fraunhofer IFF.

Let's personalize your content