Hatch report finds NOVONIX dry cathode synthesis process offers cost and waste reduction improvements

Green Car Congress

SEPTEMBER 12, 2023

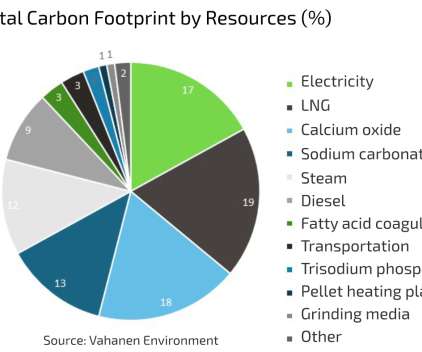

a global engineering consultancy firm, has delivered its report that evaluates NOVONIX’s all-dry, zero-waste cathode synthesis process. The Hatch study found that NOVONIX’s process may potentially reduce power consumption by an estimated 25% and practically eliminate waste byproduct generation over the conventional process.

Let's personalize your content