Dürr provides CATL with solvent recovery technology for electrode production in Germany

Green Car Congress

DECEMBER 19, 2022

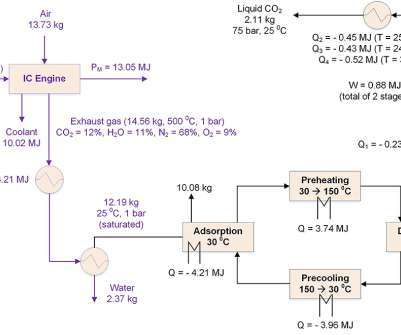

The order comprises several systems based on an eco-friendly process for solvent recovery in production. The plant in Thuringia is CATL’s first production site in Europe. Without this system, the exhaust air requires thermal oxidation, which would result in additional CO 2 emissions. Dürr’s Sorpt.X

Let's personalize your content