Rice U team creates low-cost, high-efficiency integrated device for solar-driven water splitting; solar leaf

Green Car Congress

MAY 5, 2020

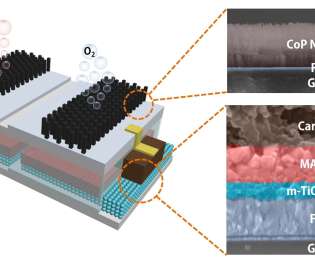

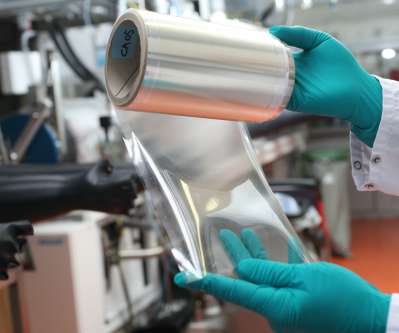

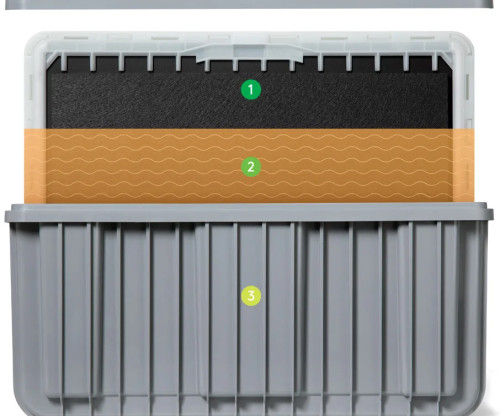

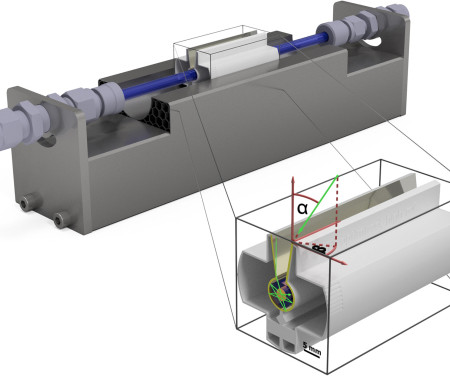

Rice University researchers have created an efficient, low-cost device that splits water to produce hydrogen fuel. The current flows to the catalysts that turn water into hydrogen and oxygen, with a sunlight-to-hydrogen efficiency as high as 6.7%. It utilizes water and sunlight to get chemical fuels. 9b09053.

Let's personalize your content