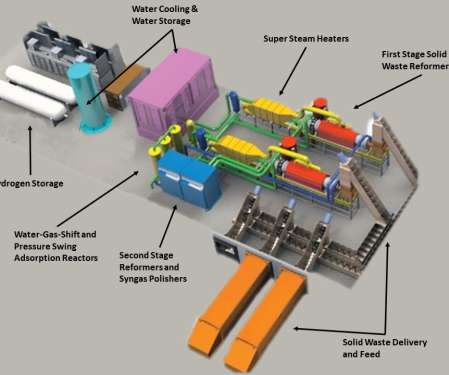

Raven SR & Hyzon Motors to build up to 100 waste-to-hydrogen hubs

Green Car Congress

APRIL 28, 2021

At the hubs, which can be built at or near landfills, Raven SR will convert mixed and multiple organic wastes, including municipal solid waste, greenwaste, food waste, medical, paper, etc. Raven can also easily process natural and renewable gases alone or combined with solid waste.

Let's personalize your content