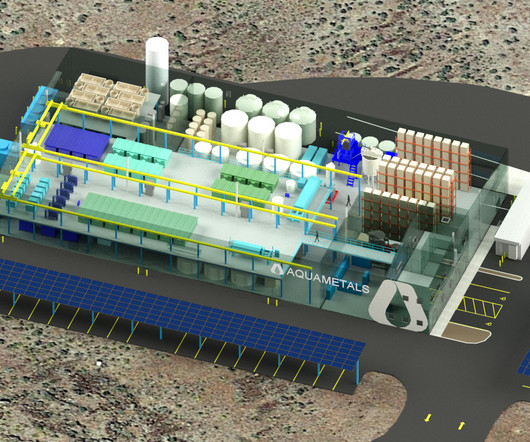

SGH2 building largest green hydrogen production facility in California; gasification of waste into H2

Green Car Congress

MAY 21, 2020

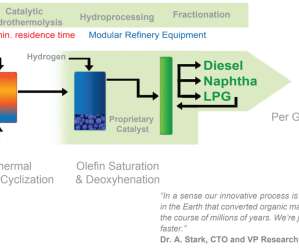

The plant will feature SGH2’s technology, which will gasify recycled mixed paper waste to produce green hydrogen that reduces carbon emissions by two to three times more than green hydrogen produced using electrolysis and renewable energy, and is five to seven times cheaper. The facility will process 42,000 tons of recycled waste annually.

Let's personalize your content