NREL plant-based epoxy enables recyclable carbon fiber; more cost-effective, lower GHG footprint

Green Car Congress

JANUARY 30, 2022

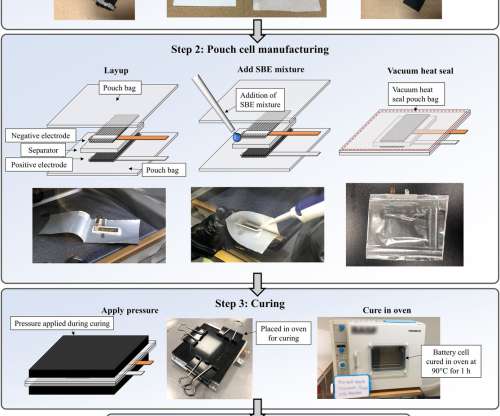

When curing, molecules in the liquid resin bind with each other and around the woven carbon filaments, hardening into a strong and rigid lattice. However, the thermoset-nature of the cured epoxy makes those superior products difficult to break apart, especially without severely damaging the carbon filaments. —Nicholas Rorrer.

Let's personalize your content