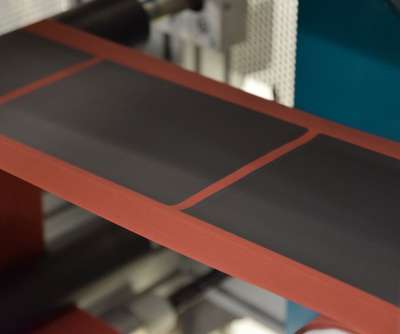

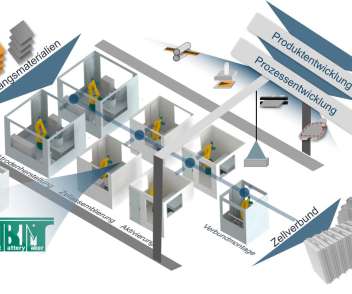

BASF and KIT to investigate opportunities of multilayered anodes for Li-ion batteries

Green Car Congress

OCTOBER 20, 2021

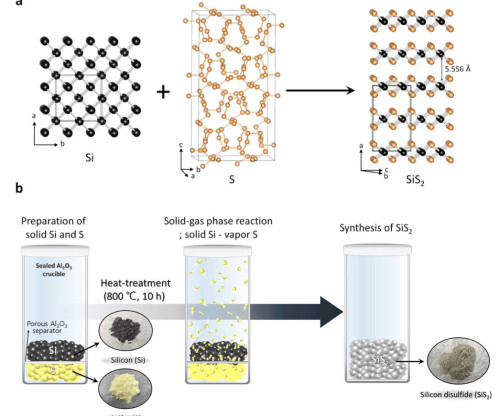

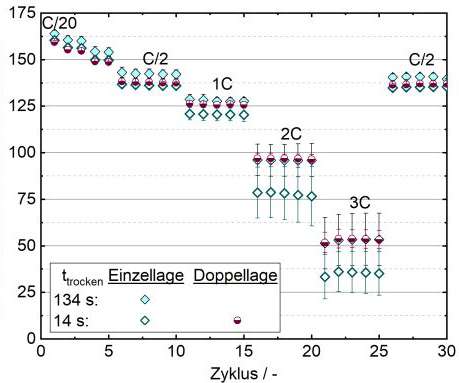

One potential solution for enhancing capacity and production efficiency of lithium-ion batteries is to subdivide electrodes into dedicated functional layers. By applying several functional layers at once, we can meet the demanding requirements of tomorrow’s lithium-ion batteries. —Prof.

Let's personalize your content