DOE awards $22.1M to 10 nuclear technology projects including clean hydrogen production

Green Car Congress

MAY 10, 2023

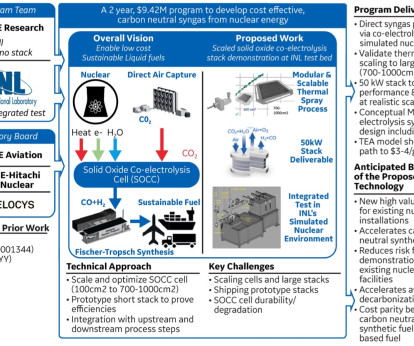

million to 10 industry-led projects to advance nuclear technologies, including two aimed at expanding clean hydrogen production with nuclear energy. A well-established downstream syngas-to-synfuel conversion process, such as Fischer-Tropsch synthesis, converts the syngas to liquid synfuel for a total projected cost of less than $4/gallon.

Let's personalize your content