IG Metall warns that Krupp Mannesmann steel plant may fail due to lack of financing for conversion to climate-neutral steel production

Green Car Congress

DECEMBER 12, 2022

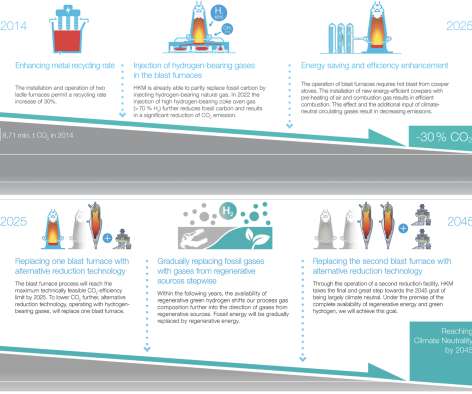

The union called on the shareholders of HKM to commit themselves clearly to the future of the traditional steel mill and to invest now in its conversion. There are currently 3,100 steel workers employed there. The French pipe manufacturer Vallourec SA wants to give up its 20% stake in HKM and withdraw from Germany.

Let's personalize your content