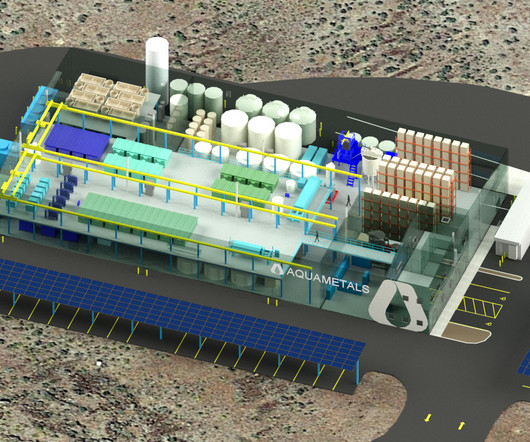

Aqua Metals and 6K Energy partner to develop low-carbon CAM precursors for Li-ion batteries

Green Car Congress

MAY 4, 2023

The companies have initiated the partnership with a non-recurring engineering (NRE) agreement to develop low-carbon technology for the conversion of critical metals—first virgin and later recycled material—into battery-grade cathode active material (CAM) precursors, which are essential to 6K Energy’s advanced cathode manufacturing.

Let's personalize your content