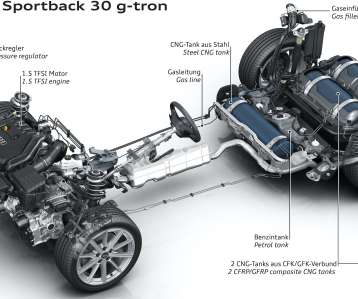

New IACMI collaboration to develop advanced carbon fiber for hydrogen, natural gas storage tanks; $2.7M DOE award

Green Car Congress

JULY 31, 2020

million from the US Department of Energy (DOE) to develop and validate technology that will reduce the cost of manufacturing high-performance carbon fiber by 25% to make composite natural gas or hydrogen fuel tanks to power cars and trucks. The Institute for Advanced Composites Manufacturing Innovation (IACMI) will receive $2.7

Let's personalize your content