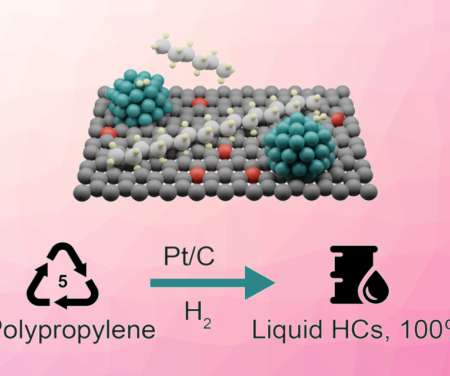

U Delaware team develops chemocatalytic process to convert waste polypropylene to lube oils

Green Car Congress

AUGUST 27, 2021

Quantification of critical properties, including pour point, kinematic viscosity, and viscosity index, indicates that the products are promising alternatives to currently used base or synthetic oils. The reaction network involves the sequential conversion of polymer into the oil with a gradual decrease of molecular weight until ?700–800

Let's personalize your content