Researchers use carbon-based anodes with “bumpy” surfaces for Li-ion batteries that last longer in extreme cold

Green Car Congress

JUNE 10, 2022

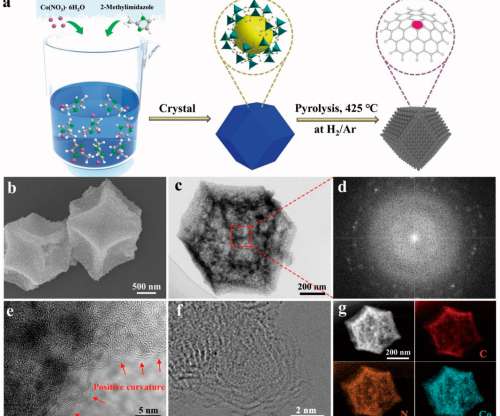

the key to addressing the low-temperature capacity loss lies in adjusting the surface electron configurations of the carbon anode to reinforce the coordinate interaction between the solvated Li + and adsorption sites for Li + desolvation and reduce the activation energy of the charge-transfer process. . … —Lu et al.

Let's personalize your content