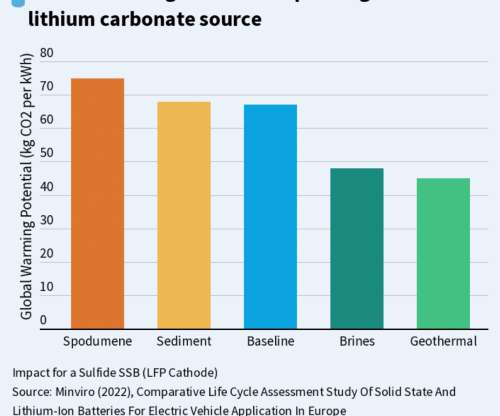

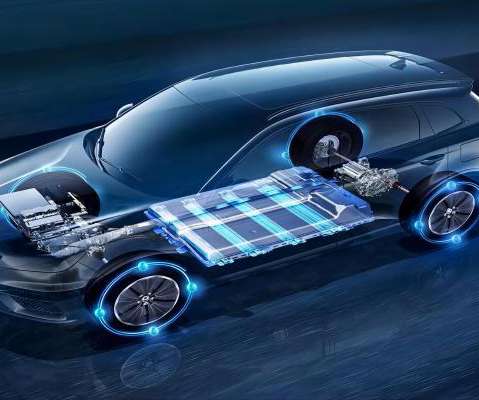

Study finds solid-state batteries could reduce the carbon footprint of an EV battery by up to 39%

Green Car Congress

JULY 21, 2022

Solid-state batteries could reduce the carbon footprint of electric vehicle batteries by up to 39%, according to a study commissioned by European environmental NGO Transport & Environment (T&E) from Minviro , a company specializing in raw material life-cycle analysis, which compared emerging solid-state technology to current battery chemistries.

Let's personalize your content