Who Really Invented the Rechargeable Lithium-Ion Battery?

Cars That Think

JULY 30, 2023

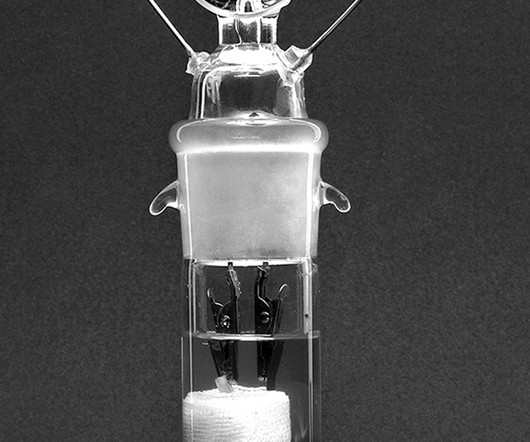

Fifty years after the birth of the rechargeable lithium-ion battery, it’s easy to see its value. By Christmas, he had developed a battery with a titanium-disulfide cathode and a liquid electrolyte that used lithium ions. Goodenough at the University of Oxford was the next scientist to pick up the baton.

Let's personalize your content