Sulfur-carbon nanofiber composite for solid-state Li-sulfur batteries

Green Car Congress

APRIL 13, 2020

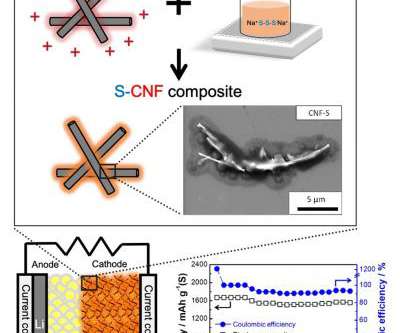

Researchers at Toyohashi University of Technology in Japan have developed an active sulfur material and carbon nanofiber (S-CNF) composite material for all-solid-state Li-sulfur batteries using a low-cost and straightforward liquid phase process. Copyright Toyohashi University Of Technology. —Phuc et al.

Let's personalize your content