RecycLiCo and Nanoramic Laboratories partner for lithium-ion battery recycling

Green Car Congress

AUGUST 6, 2023

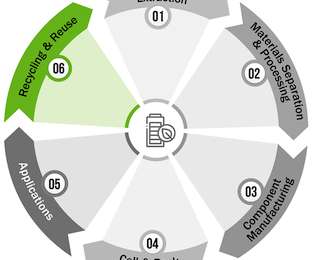

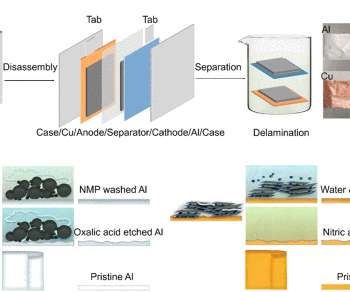

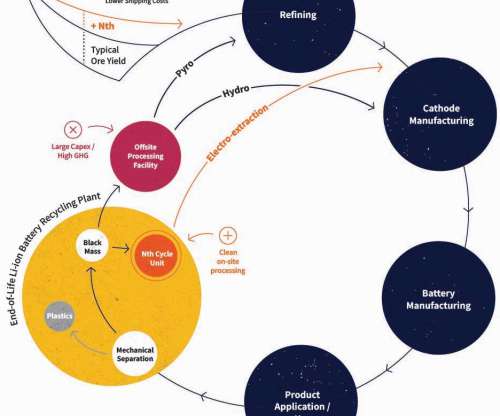

RecycLiCo Battery Materials and Nanoramic Laboratories announced a strategic collaboration with the goal of optimizing the complete life cycle of lithium-ion batteries. Nanoramic’s NMP-free and PVDF-free electrodes offer a solution to potential bans on per- and polyfluoroalkyl substances (PFAS) in lithium-ion batteries.

Let's personalize your content