Virginia Tech team demonstrates green manufacturing method for Li-ion batteries

Green Car Congress

APRIL 25, 2020

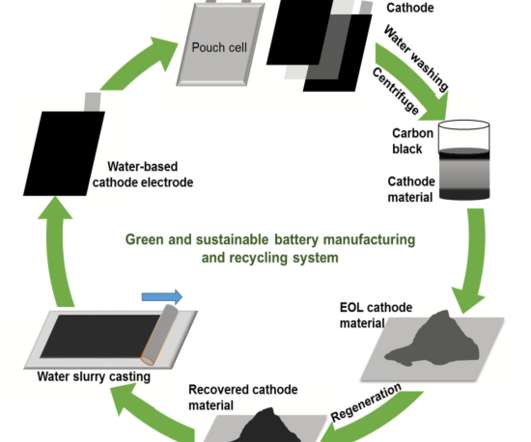

Mass production of LIBs can result in environmental concerns during battery manufacturing and disposal. million kg per year of NMP is used for depositing the cathode layers for a battery manufacturing plant producing 100,000 packs per year of 60 kW, 10 kWh plug-in hybrid vehicle (PHEV) batteries. —Li et al.

Let's personalize your content