GODI India achieves LFP BIS certification for indigenous Li-ion cells | Autocar Professional

Baua Electric

JANUARY 18, 2024

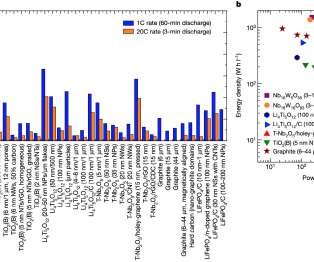

GODI India Private Limited, a Hyderabad-based lithium-ion cell R&D and manufacturer, has become the first Indian company to attain LFP BIS certification for its Lithium Iron Phosphate (LFP) Li-ion cells. The company had earlier secured BIS certification for its NMC811 cathode material-based Li-ion cells in mid-2022.

Let's personalize your content