Amprius unveils ultra-high-power-high-energy lithium-ion battery

Green Car Congress

AUGUST 4, 2023

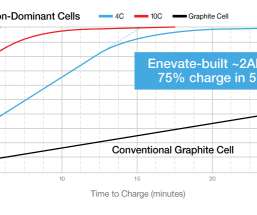

Amprius Technologies, a developer of next-generation lithium-ion batteries with its Silicon Anode Platform, unveiled its newest ultra-high-power-high-energy lithium-ion battery. Moreover, it extends flight range by as much as 50% and increases payload capacity.

Let's personalize your content