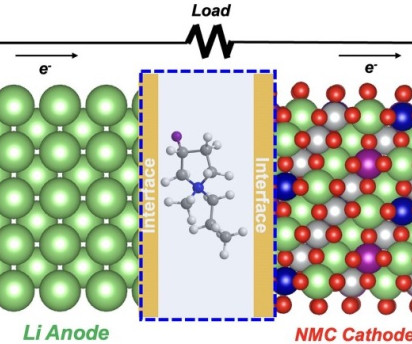

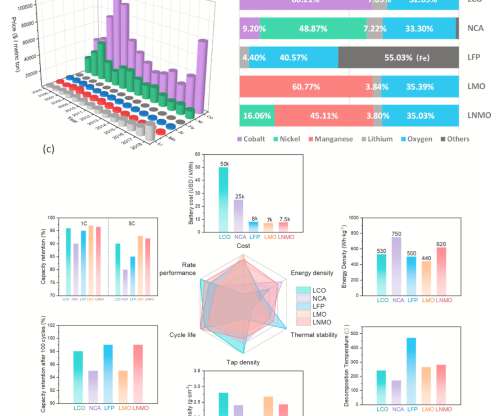

UC Irvine team creates long-lasting, cobalt-free, low-nickel lithium-ion batteries

Green Car Congress

JUNE 16, 2023

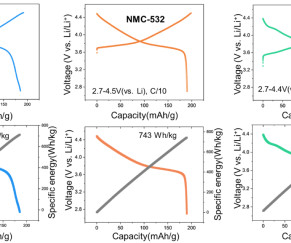

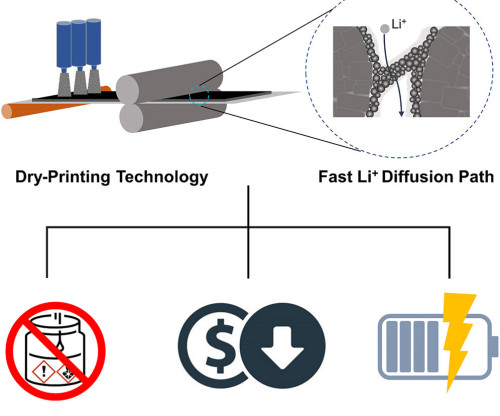

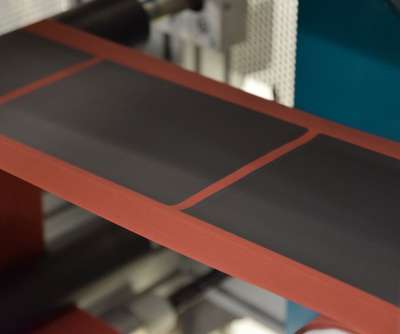

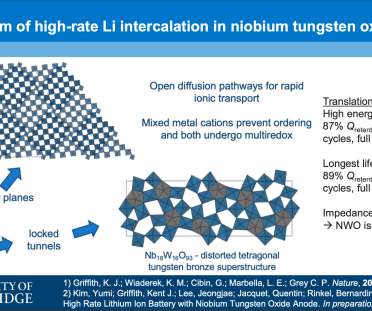

In a discovery that could reduce or even eliminate the use of cobalt—which is often mined using child labor—in the batteries that power electric cars and other products, scientists at the University of California, Irvine (UCI) have developed a long-lasting alternative made with nickel. Further, the metal’s cost keeps climbing.

Let's personalize your content