Stellantis is about to test the first-ever production-line lithium-sulfur batteries

Electrek

MAY 10, 2024

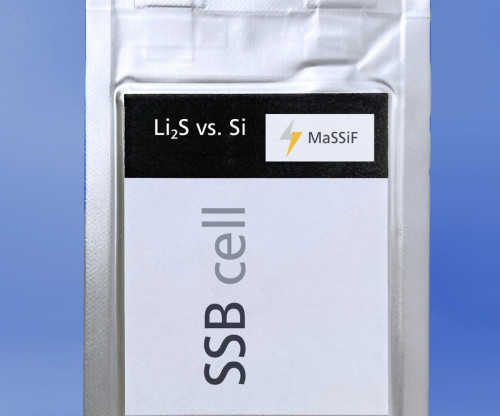

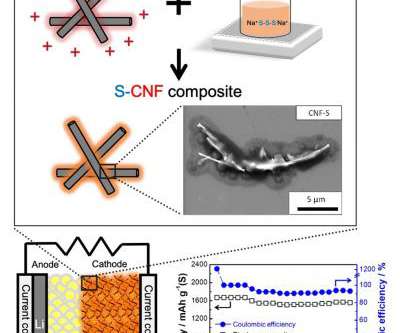

In a milestone, supermaterials trailblazer Lyten has shipped lithium-sulfur (Li-S) batteries to Stellantis and other US and EU OEMs for testing.

Let's personalize your content